UPK-T Series

UPKnife Tools

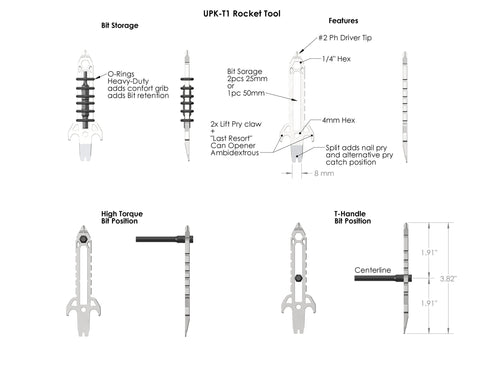

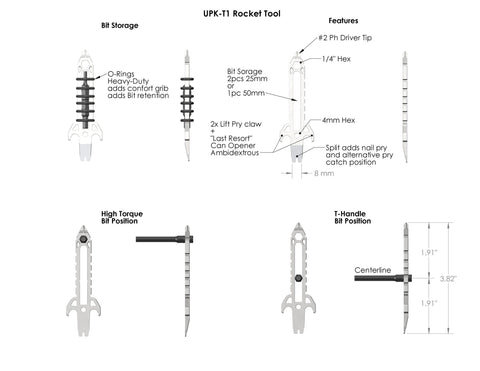

The Rocket tool comes in two flavors, a Cast version, which should be consider for lighter duty EDC and the billet Heavy Duty (HD) version which is for heavy duty use.

The primary difference is the way the Rocket Tools are made and from what, which creates the price difference. Casting is a hot pour of liquid alloy using lost wax casting, in this method the liquid funnels down a wax formed ceramic mold tree and cools in each respective part of the tree, this looks like an upside down tree with the trunk becoming broader towards the top. It creates parts quickly without the need for machining, but it also results in a less dense metal alloy, typically 90-95%, and is not as pure as a billet metal build.

In a HD billet version, the Rocket Tool is cut from a solid plate of high purity alloy, 154CM Stainless in this case, and then machined down into the part, so the substrate is a solid pure metal with higher density and better material properties then the same alloy poured in a casting.

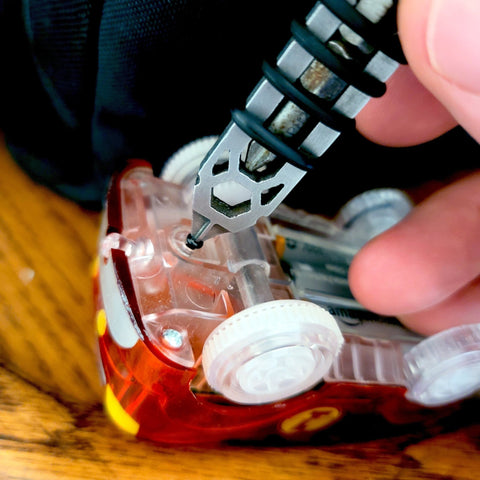

It is recommended to purchase the Cast version when you mainly have regular Dad duties like changing batteries in toys or accessing occasional panels or covers made typically in plastic.

Its recommended to go with the Billet when you know you will use your Rocket Tool a lot, accessing rusted screws in maintenance panels, or finding yourself in inconvenient places often but needing a more robust tool at the ready. If you need screwdriver all the time, but find them out of reach often, this will save you some trips.

If your Primary use is prying, both tools are adequately built to handle just about any pry task. Always feel free to purchase the Cast version to try it out!

CYBER HUNT DISCOUNT CODE PIECE: xxxxxxxxxxxxxxSLIxxxx